Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

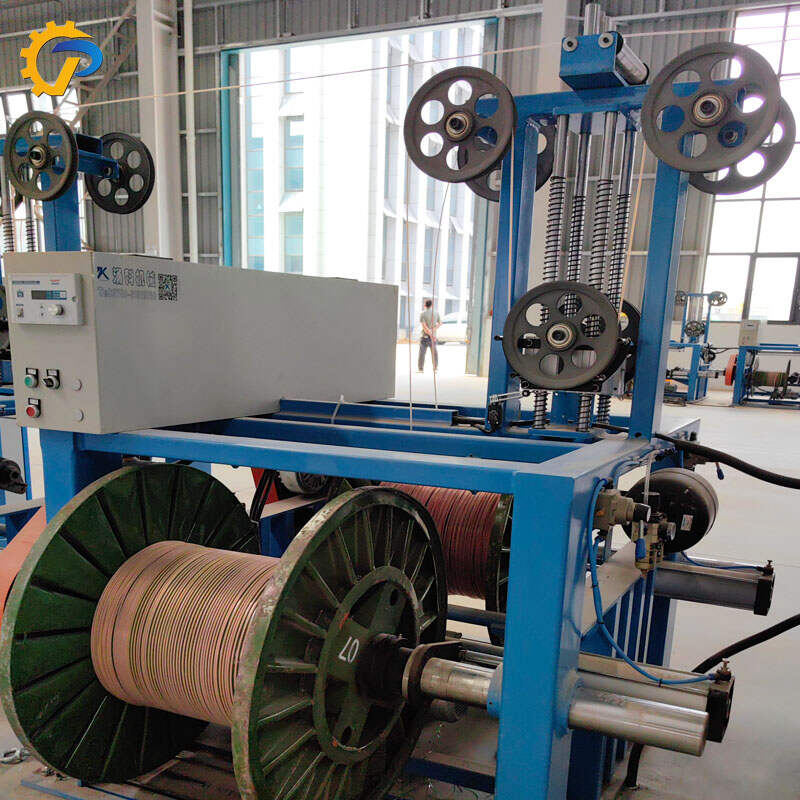

800 Cantilever single twisting machine

The 800 Cantilever Single Twisting Machine is an advanced stranding and bunching solution designed for high-speed precision cable manufacturing. Ideal for use in IT, aerospace, military, and medical applications, it supports the twisting of multiple wire types including bare copper, tinned, silver-coated, and enameled wires. Its cantilever structure and computer-controlled system ensure uniform tension, reduced wire bending, and consistently high-quality output while helping reduce production costs by up to 40%.

Product Features

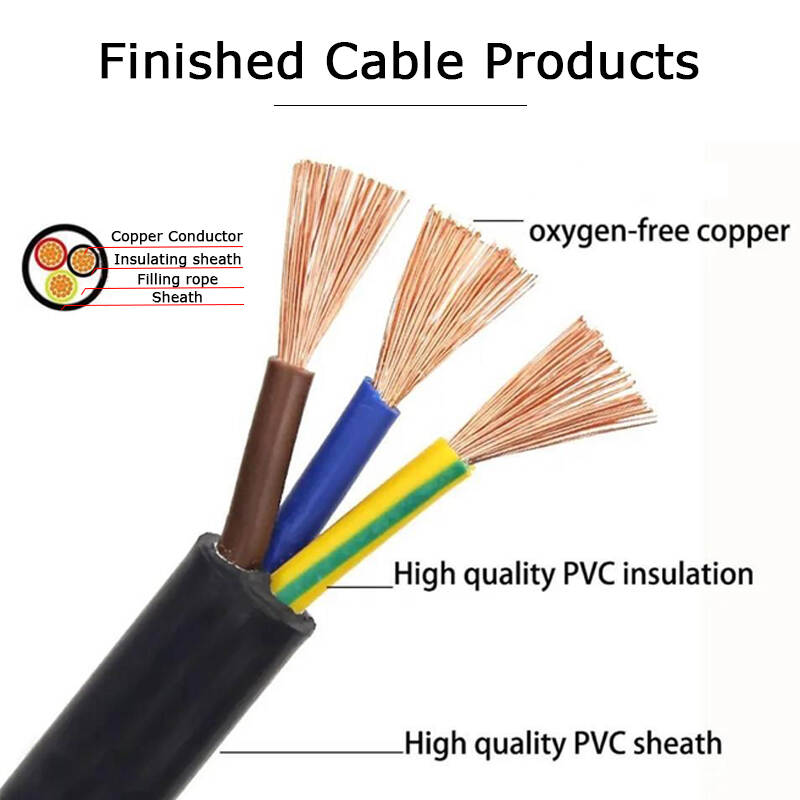

High-Precision Twisting for Multi-Wire Applications

Capable of twisting over 7 wires including bare copper, tinned, silver-jacketed, and enameled wires, as well as core wire stranding for conductor sizes from φ1.5mm to φ12.0mm.

Cantilever Structure with Low Rotational Inertia

Utilizes a cantilever design with small rotational inertia, allowing for high-speed, stable operation and improved product consistency during the twisting process.

Computer-Controlled Pitch Without Capstan or Dynamic Plate

Equipped with a computer system to control the pitch directly, eliminating the need for capstan and dynamic plate, ensuring consistent cable tension and reducing cable path length.

Reciprocating Take-Up Box for Precision Winding

The take-up box moves reciprocally, ensuring the twisted wires are evenly and precisely laid onto the take-up bobbin, improving overall winding accuracy.

Optimized Veer Wheel Design to Minimize Wire Bending

An enlarged veer wheel diameter minimizes the bending angle of the wire, which significantly enhances the finished cable’s structural quality and durability.

Product Advantages

Reduces Production Costs by 40%

Designed with efficiency in mind, this machine helps manufacturers cut upfront cable production costs while boosting productivity.

Widely Applicable Across High-Tech Industries

Trusted for use in aerospace, robotics, telecommunications, 5G, automotive, medical, and defense sectors for its versatility and reliability.

Improved Cable Safety and Strength

Reduces the risk of rod cracking and other common issues associated with traditional cable-laying machines, even during high-speed operation.

Uniform Tension Ensures Cable Quality

The pitch control system maintains consistent wire tension, which directly contributes to superior cable structure and fewer defects.

Compact Yet Powerful Structure

With a smaller footprint and enhanced rotational dynamics, it saves space while delivering industrial-level performance.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost